Manufacturing MythBusters: Weld Appearance vs Strength

The Myth

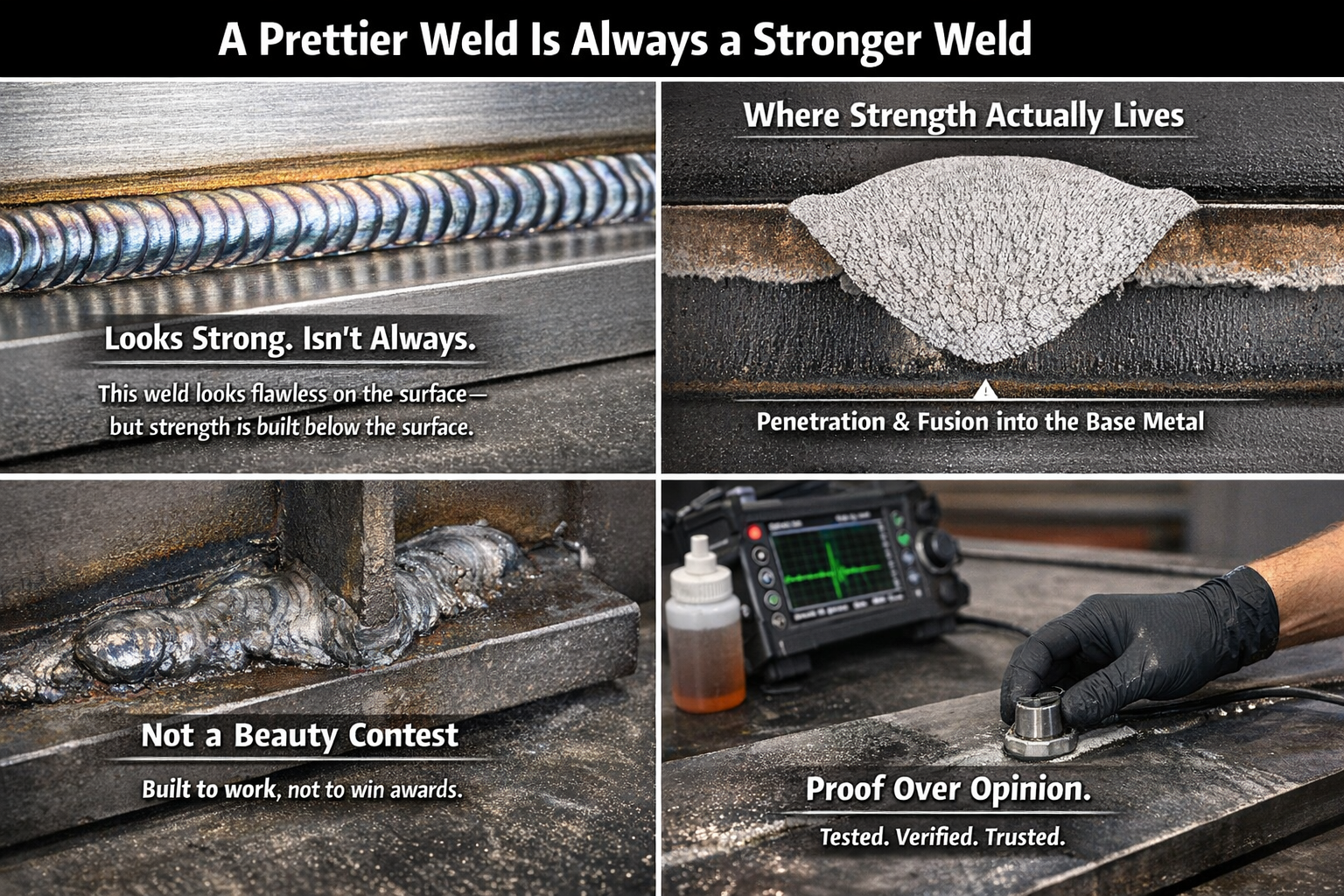

If a weld looks perfect, it must be strong. Clean bead, even ripples, textbook “stack of dimes”. That’s what quality looks like… right?

It’s a common belief and that's not always the case.

Why This Myth Exists

People trust what they can see. When something looks clean and uniform, we assume it was done right. Welding just happens to be very visual, and social media hasn’t helped. Scroll long enough and you’ll see beautiful welds with no context: no load, no service conditions, no long-term performance.

It’s easy to believe appearance tells the story when, in reality, it tells only a small part of it.

What Really Matters

Weld strength doesn’t live on the surface. It comes from penetration into the base material, proper fusion, correct heat input, joint prep, and following the right procedure for the application.

A weld can look flawless on the outside and still have poor fusion at the root. That weakness won’t show up in a photo, but it will show up in service, usually when it matters most.

What We See in the Real World

We’ve seen welds that look incredible crack far sooner than expected because they were under-penetrated or overheated. We’ve also seen welds that weren’t particularly pretty pass testing and perform exactly as designed for years.

The difference isn’t talent or effort...it’s process. Welds built to procedure consistently outperform welds built for appearance.

Why It Matters

This misconception creates problems on both sides. Customers may reject perfectly acceptable welds based on looks alone. Welders feel pressure to chase appearance instead of structural integrity. Projects take longer, cost more, and require unnecessary rework.

Visual inspection has its place but it’s only one piece of a much bigger quality picture.

The Takeaway

A pretty weld can be strong, and strong weld

doesn’t have to be pretty.

In manufacturing, performance beats appearance every time.